Commitment to Safety, Security and High Quality

Reliable Quality that Supports “Pleasant Taste”

To deliver safe, secure and high-quality products to our customers, TAKESHO carries out various initiatives.

Obtained FSSC22000 Certification

To deliver safe, secure and high-quality products to our customers, we renew FSSC22000 certification, an international standard for food safety management system regularly since our main factory were certified in 2017. Quality is the top priority at every step of our operations, including food ingredients management, production environment maintenance, and product quality inspections.

Strict Allergen Control

We secure a flow line where food ingredients and products do not cross each other and use individual rooms for weighing and manufacturing each product. In addition, positive pressure is applied in the production room to control the air flow in the entire production area. We also wash and dry the machines and equipment for each product to ensure thorough allergen control.

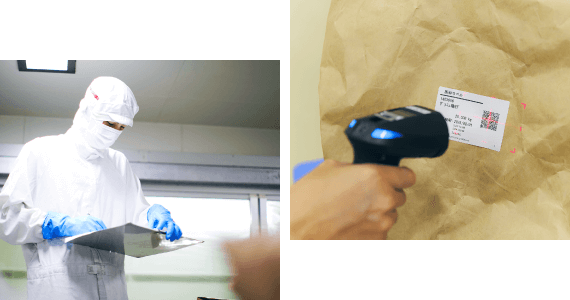

Sanitation in Manufacturing Facilities

We have detailed step-by-step procedure to enter the manufacturing facility such as washing hands and air showering. We also change uniforms after manufacturing each product to prevent allergen contamination.

Preventing Contamination

Our manufacturing facility has one-way flow line from weighing food ingredients to blending and filling powder in the package. Since everything flows in one direction, cross-contamination of food ingredients and products is prevented.

To Deliver High Quality Products to Our Customers

We check for product quality at various steps from procurement of food ingredients to shipment of products. We also keep track of the latest information of food ingredients, such as origin and allergens to respond promptly to customer inquiries. To deliver safe and high-quality products, we ensure thorough quality control by carrying out product inspections such as microbiological examination and sensory evaluation on a dairy basis.

Production Process

Procure and Manage Ingredients

Foreign materials and allergen contamination risks are prevented by countermeasures such as thorough testing at receipt and segregating allergens in labeled storage racks.

Measure

Ingredients are picked up and weighed following the “one blend – one weighing room” principle to prevent allergen cross-contact.

Blend, Fill, and Seal Product Packaging

Weighed ingredients are blended and foreign material removal is introduced during the filling and packing step. We offer a variety of packaging format options and sizes upon your request.

Test and Ship

Various tests (physical and chemical tests, hygiene tests, and sensory tasting) are done before shipping to make sure the seasoning blends meet all the required safety and quality standards.

Our Commitment to "Pleasant Taste"

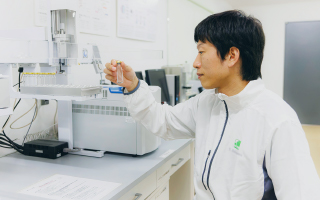

"Science of Palatability"

We are putting effort into initiatives of "Science of Palatability", our attempt to visualize the characteristics of food products by combining sensory evaluation and instrumental analysis.

Collaboration with Research Institutions and Companies

We collaborate with research institutions and companies in Japan and overseas to conduct joint research.

Through these research, we aim to develop our initiatives of “Science of Palatability” and to enhance the value of food materials.